Electrical fire hazards are shockingly common. They’re responsible for 13% of non-home structure fires and they cannot be extinguished with water. To get a reliable protection from electrical fires, explore Honeywell’s Electrical Cabinet Suppression (ECS) System – a world-class offering from the world leader in fire safety solutions.

The same electricity we rely on can also cause of a lot of devastation in the form of fires. Some of the many causes of electrical fires are:

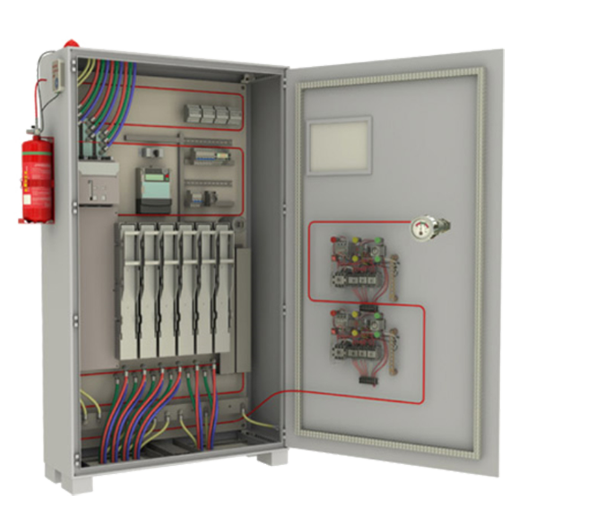

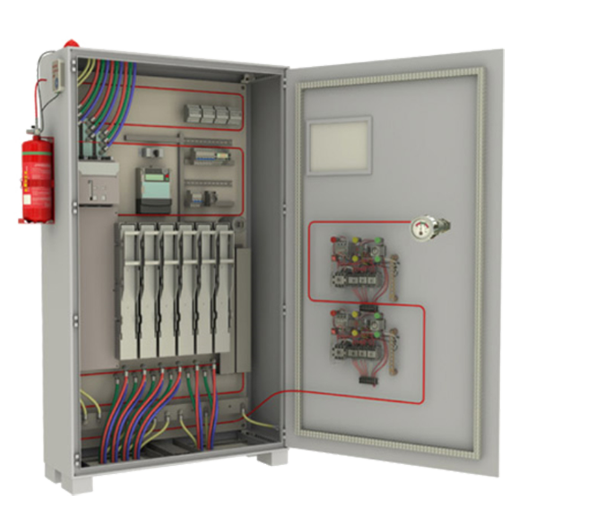

Designed to protect electrical enclosures/circuitry, Honeywell’s comprehensive, pre-engineered ECS system reduces the risk of electrical fires, and prevents potential devastation to business and property. Not only does it protect business assets, it also prevents downtime and ensures business continuity. Perfect for ‘microenvironments’ where fire hazards are likely to be in the enclosed space, it leaves out no residue behind which eliminates the need for an extensive area clean up.

Keep your premises safe from the damaging effects of fire hazards by installing Honeywell’s Electrical Cabinet Suppression (ECS) System. As a fully automatic and pre-engineered suppression system, it comes in two variants of Indirect Low Pressure (ILP) and Direct Low Pressure (DLP). Besides a 24 hour battery backup, LCD display, open door alarm and a visual alarm, this system provides smart protection with 24x7 monitoring and control with a monitored alarm and fault circuits to ensure safety for business assets.

The ECS-250 and ECS-252 are Direct Low Pressure systems filled with 1.13 kg of non-toxic and odourless FK-5-1-12 fire suppression clean agent. The system operates at a working pressure of 195/240psi (13.5/16Bar) and a temperature range of -17.8° C to 54.4° C. It comes with an EOL adapter (with gauge) and cylinder valve Assy, 4 rubber grommets, 25 plastic loop clamps and a cylinder mounting bracket.

The assembly is installed on-site with the included bracket. The Heat detection tube is installed inside the electrical panel using the included rubber grommets and plastic loop clamps. The tube is pressurised with dry Nitrogen to 13.5/16 Bar using the Filling Adapter and connected to the cylinder valve assembly on-site. The EOL Adapter with gauge is connected at the end of the tube. The pressure gauge is kept outside the electrical panel for clear visibility and to ease inspection. The ball valve on the cylinder valve assembly is kept in the “ON” position to complete the installation and commissioning.

ECS-252 provides a dual valve outlet as against ECS-250 which has a single valve outlet port.

.png)

A world-class range of products specifically designed to provide protection from electrical fires.